What Is Hot Stamping?

Hot stamping is a process in which an engraved image, hot stamping die or type, is heated then forced down against a part with a marking foil sandwiched in between. The area where the die meets the part, is where the ink from the foil is left behind. Though this is a very simplified description of hot stamping, it is the basis of the process and where you need to start.

Why Choose Hot Stamping?

Hot stamping can be used to mark a multitude of different material, the most common being plastics. We have sold machines for stamping wire insulation, pencils, and paper. Just to name a few.

The best part about hot stamping is that it’s a dry process. You don’t have to have a degree in chemistry to operate a hot stamping machine because you don’t need to worry about mixing inks.

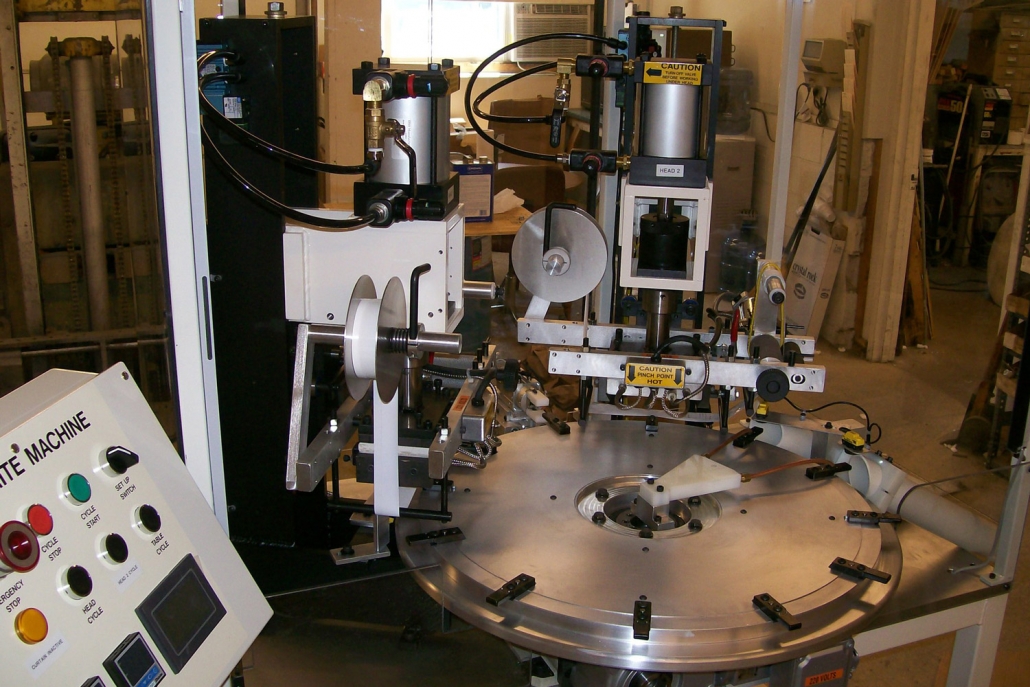

You simply attach a die to the heated plate, load a roll of hot stamping foil, pop a part in the fixture and you are ready to go.

Hot stamping is a very permanent process. When a part is marked with a properly formulated foil, it can withstand some very harsh conditions. When using a metal die on a plastic part, you can actually brand the part at the same time. So, if the color should fade or wear off the branded image will remain.

Creating the Image

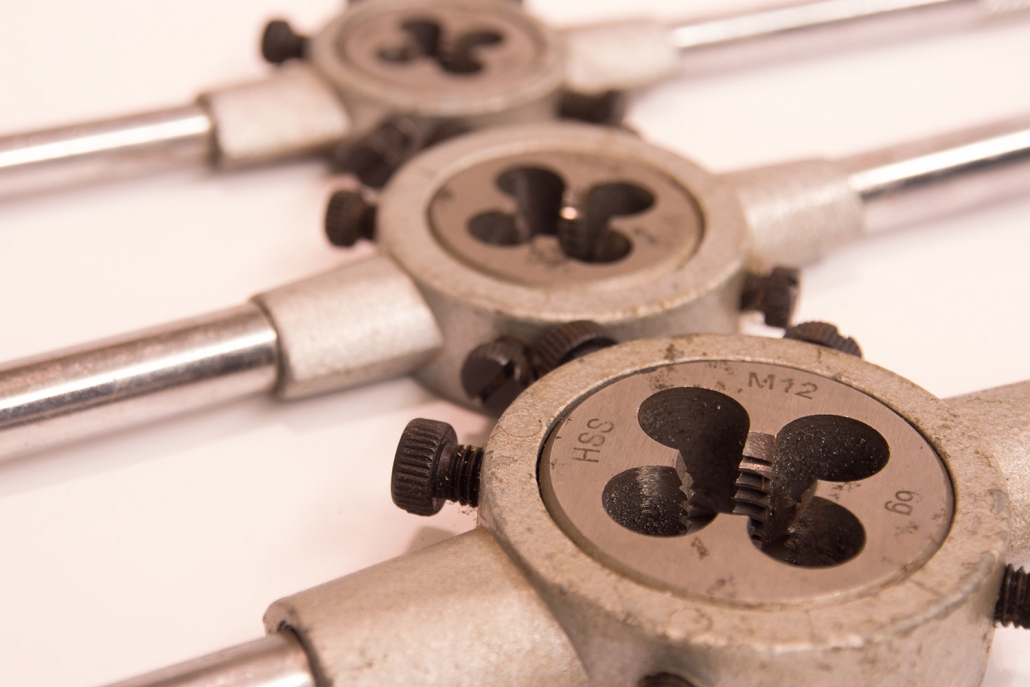

You have a few options when it comes to the hot stamping die itself. First, there are metal dies which come in these basic materials; magnesium, copper, brass and hardened steel. Then there are silicone rubber dies, which have varying durometer’s or degrees of hardness. The most important aspect of creating a hot stamping die is the artwork. It’s very critical to have good artwork. Either in the camera ready form or a digital file that the engraver can work with.

Fixturing the Part

One of the most important pieces to the hot stamping puzzle is supporting the part you plan to mark. The hot stamping process itself requires a great deal of pressure. We normally use as a guideline, 500 psi for every square inch of marked area. With this in mind you can see were the pressure can add up quickly. When you are putting that much pressure down on the part, you need to be certain that the area you plan on marking can be well supported.